Understanding Dual Mass Flywheel Failure

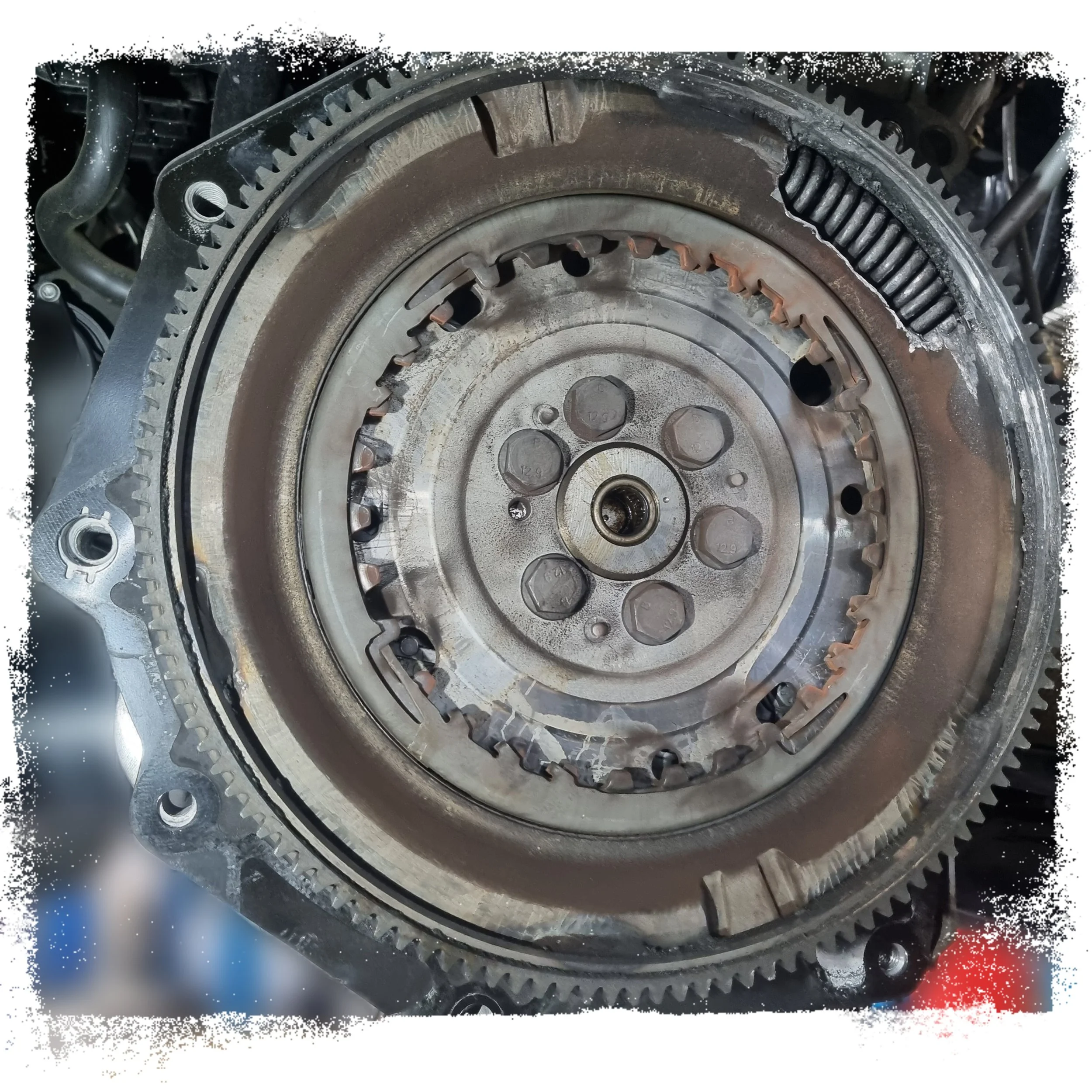

The dual mass flywheel (DMF) is a key part of many modern vehicles, particularly those with DSG or other advanced transmissions. It sits between the engine and gearbox, absorbing vibration and smoothing out torque delivery.

Why They Fail

Dual mass flywheels are designed to reduce drivetrain shock, but over time the internal springs and damping components can wear out. Contributing factors include:

High mileage and normal wear

Aggressive acceleration and towing heavy loads

Clutch or transmission faults that cause extra stress on the flywheels interna dampener.

Symptoms of a Failing DMF

When a DMF starts to fail, you might notice:

Rattling noises from the bellhousing area, especially at idle or when shutting the engine off

Harsh vibrations felt through the floor, your seat or steering wheel

Judder during take-off that isn’t caused by the clutch pack

In severe cases, difficulty engaging gears or sudden loss of drive

We’ve seen vehicles where rust and debris build-up around the flywheel, adding to the noise and imbalance.

Our Approach to DMF Diagnosis and Repair

Diagnosis starts with listening for tell-tale noises and checking for excessive rotational play in the flywheel once the transmission is removed. If wear or damage is confirmed, we replace the DMF with a high-quality OEM-spec unit.

It’s also common to replace the clutch assembly at the same time, as the two components work closely together and share similar labour for access.

Why Ignoring a DMF Fault is Risky

A completely failed DMF can damage the starter motor, transmission input shaft, dual clutch assembly, front transmission housings and even the engine crankshaft. If your car has symptoms of flywheel failure, it’s worth getting it checked sooner rather than later.